Description of soldering iron tip cleaning sponge

- Product Material: The soldering iron tip cleaning sponge is made of wood pulp fiber, which is relatively resistant to high temperatures. The sponge is relatively thick, with high cleaning efficiency and convenient for daily use

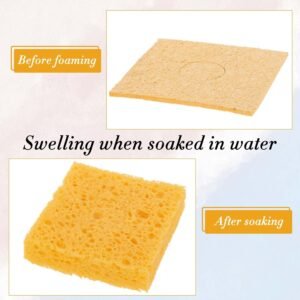

- Product Size: The high-temperature soldering iron tip cleaning sponge is 6×6cm/2.36×2.36in in size and is made of thickened wood pulp fiber sponge. The expanded thickness after soaking in water is 10mm/0.39in

- Package Includes: You will receive 10 soldering iron tip cleaning sponges, which are easy to use and in large quantities. They can be used with soldering iron racks or temperature-controlled soldering iron systems to meet your various needs

- Easy To Use: Soak the yellow cleaning sponge in water, squeeze out about 40% of the water after expansion, and then wipe the soldering iron tip that needs to be cleaned on the cleaning sponge. The soldering iron tip will instantly be as bright as new, and can remove solder residues and keep PCB components clean

- Wide Range Of Uses: This square cleaning sponge can not only be used to clean soldering iron tips, but also can be used for car cleaning sponges, desktop sponges, kitchen cleaning, etc., which is enough to meet your daily needs

Material advantage

Unlike traditional polyurethane foams, cellulose sponges are derived from renewable plant fibers and are excellent in terms of sustainability and environmental performance. Professionally maintained cellulose sponges can be recycled thousands of times and are far more durable than conventional cleaning tools. After the end of the product life cycle, it can be completely degraded in the natural environment, and truly achieve zero pollution ecological closed loop.

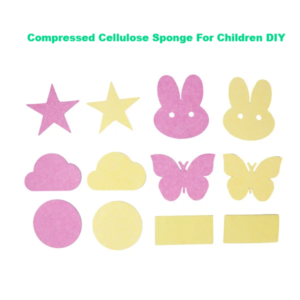

We offer a full range of cellulose substrate solutions:

• Regular wet sponge (ready-to-use)

• High density compressed sponge (transport optimized)

• Dry and wet cleaning cloth series

Innovative compression technology

Through a patented hot pressing process, we compress standard thickness cellulose materials to 10% of their original volume. This physical reconstruction technique offers significant advantages:

Storage efficiency: Increased capacity per container by 900%

Logistics economy: 65% reduction in transportation costs and 40% reduction in carbon emissions

Storage flexibility: Support for three-dimensional warehousing (see the Space Optimization Guide for details)

Ease of use: Restore the original form within 3 seconds of water, and maintain 100% functional characteristics

Multi-domain application scenarios

Breaking through traditional cleaning uses, compressed cellulose materials show unique value in special fields:

▫️ Emergency rescue: Life raft with water suction device (in accordance with SOLAS standard)

▫️ Scientific research testing: Special media for microbial sampling (FDA approved)

▫️ Industrial flaw detection: electrostatic pinhole detection carrier

▫️ Medical field: Sterile surface sampling tools

▫️ Commercial application: expandable advertising media (display 3D content after absorbing water)

Technological innovation point

This product line uses molecular structure-oriented compression technology to achieve a breakthrough reduction in transportation volume while maintaining the natural porosity of cellulose (85%±3%). When activated, the expansion coefficient reaches 10:1, and the water absorption rate maintains the industry-leading level of 300ml/min.